In the process of time history analysis by NIDA, a simple, accurate and efficient method for determining the plastic hinge(s) is used to capture the progressive strength and stiffness degradation of the structure under an earthquake attack.

The basis of the plastic hinge method is cross-section plastification. Material yielding is accounted for by zero-length plastic hinges at one or both ends of each element. Plasticity is assumed to be lumped only at the ends of an element, while the portion within the element is assumed to remain elastic throughout the analysis.

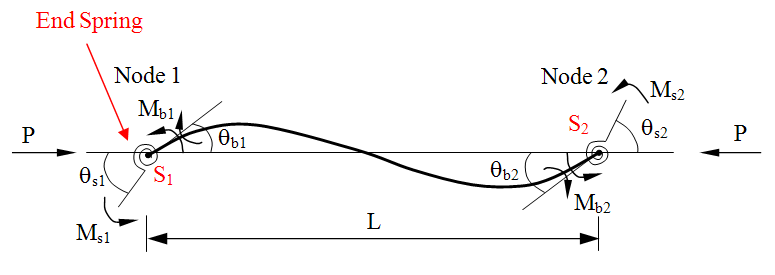

In NIDA, two predefined section springs (see Figure1), which are used to simulate plastic hinge, will be set at the two ends of each beam-column element. The end section springs will be finally formulated into the element stiffness matrix of the curved stability function beam-column element (Chan and Gu 2000) which has been widely used for second-order P-D-danalysis. More details about the plastic hinge method can be referred to Chan and Chui (2000).

Figure1 Internal Forces of the Curved Element with End Springs

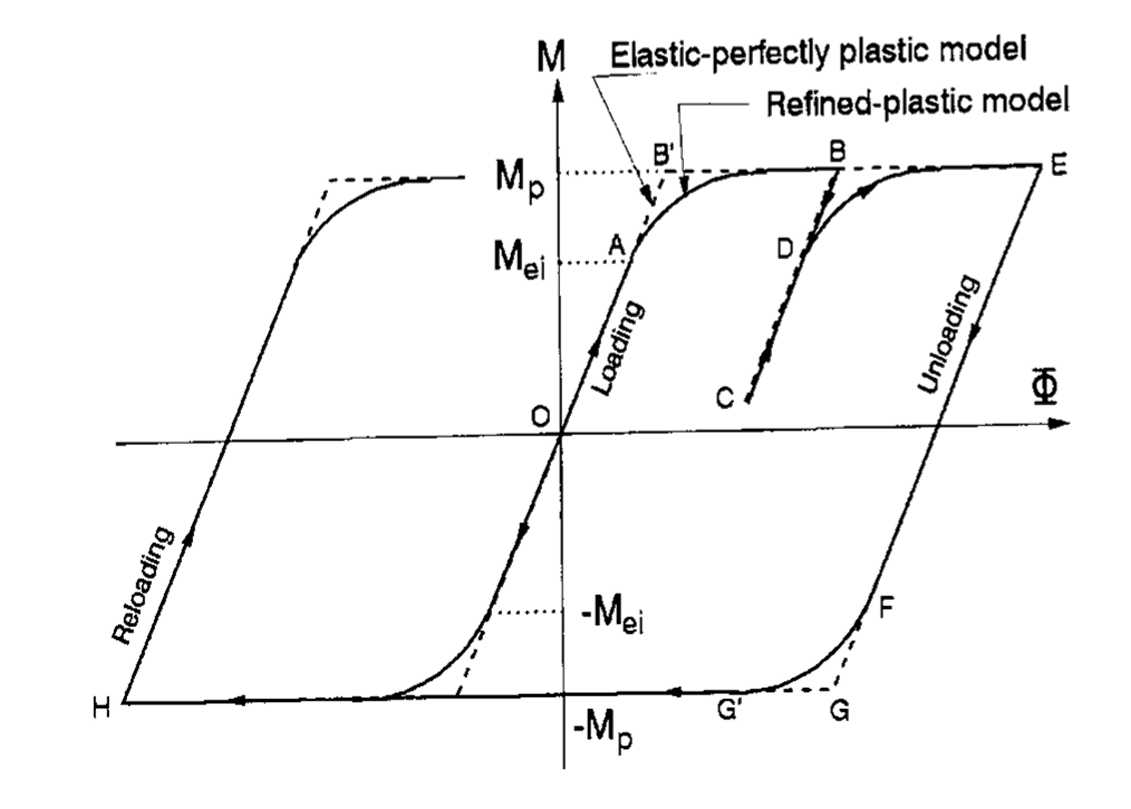

The hysteresis model for steel material used in NIDA is shown in Figure2. As illustrated in this figure, initial yielding occurs at point A when the first yield moment capacity Mei is attained. On the curve AB, the gradual yielding occurs and the plastic moment capacity Mp is reached point B. When unloading takes place at point B, gradual yielding characteristics disappears and the path follows the line BDC in which the moment at point C is less than the initial yield moment Mei at point D. On reloading, the path moves along the line CD under the perfectly elastic state and then follows the curve DE under the partial yielding state. Similarly, under unloading conditions at point E, the path moves along EFG’H.

Figure2 Elastic-Perfectly Plastic & Refined-Plastic Models